Worm and Worm Wheel Manufacturer

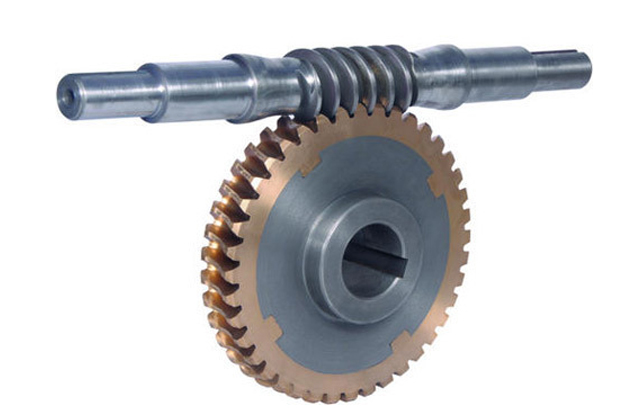

A worm drive is a gear arrangement in which a worm, a gear in the form of a screw, mates with a worm gear, smaller in quality than a spur gear and also called a worm wheel. Like other gear arrangements, a worm drive can reduce rotational speed or enable higher force to be transmitted. A gearbox designed using a worm and worm-wheel will be well smaller than one made from plain spur gears and has its drive axes at 90° to each other. Indo Mech Engineer can construct worm wheels, worm & pitch with a maximum diameter.

We are major manufacturer of Worn and worm wheel, Supplier of worm wheel, Exporter of worm wheel; maintenance of worm wheel in Ghaziabad Delhi India. Managed by our experienced professionals, Engineers is offering superior quality Worm Wheel to our prestigious customers. This worm wheel is designed and manufactured using superior grade raw material that is root from our trusted vendors of the market. Offered wheel is related to a spur gear and is mainly used in rolling mills and conveyor machines. Application of Indo Mech Engineer, which is similar to a standard prodding and the worm, which is a rounded gear that resembles a screw, allows for smaller gearboxes or planetary drives, while retaining torque or power. It is common for Indo Mech Engineer to have reductions of 20:1, and even up to 300:1 or greater.

Typical Indo Mech Engineer include an unique ability which other gearing components do not have .The worm can unforced spin the worm parts, but the “gears” are not able to operation and fully rotate the worm. What’s the rational motive behind this inability to rotate the gear worm? The angle is not deep enough on the worm, so when the gear attempts to rotate the worm, high resistance pressure between worm line and gear parts keep the worm stuck in point. An Indo Mech Engineer system consists of a worm and worm wheel and is the most compact type of gear system. Due to the compact design,Indo Mech Engineer reducers are able to be placed in comparatively small spaces and provide high-ratio speed reduction. Worm gears are known to run smoothly and softly, as long as they are properly decorated and lubricated. Indo Mech Engineer is typically manufactured by goblin with a goblin or cutting tool very similar to the worm that the gear mates with. The worm may be turned, hobbed, milled, or ground. Indo Mech Engineer is able of manufacturing worm gears in both standard and custom sizes. Our highly skilled team commutes their many years of experience and our sizeable fleet of instrumentality to produce high quality gears with great preciseness.

Capabilities of Worm

Diameter-: 0.5” – 9.5”

Axial D. Pitch-: 48 to 2

Capabilities of Worm Wheel

Diameter-: 0.5” – 36.0”

Axial D. Pitch-: 48 to 2

For custom worms and worm wheel made to your exact specifications, you can feel confident turning to Indo Mech Engineer.